drivecoupling.net

drive coupling en español

drive couplings escalator

ecoflam drive coupling

engine drive coupling

elastic drive coupling

elastomeric drive coupling

enfield drive coupling

drive coupling flange

Drive coupling

Manufacturer supplier exporter of drive coupling

About Us

We specializing in the production of Agricultural Gearbox, PTO Shafts, Sprockets, Fluid Coupling, Worm Gear Reducers, Gears and racks, Roller Chains, Sheave and Pulleys, Planetary Gearboxes, Timing Pulleys, Shaft Collars and more.

We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.

drive coupling gear

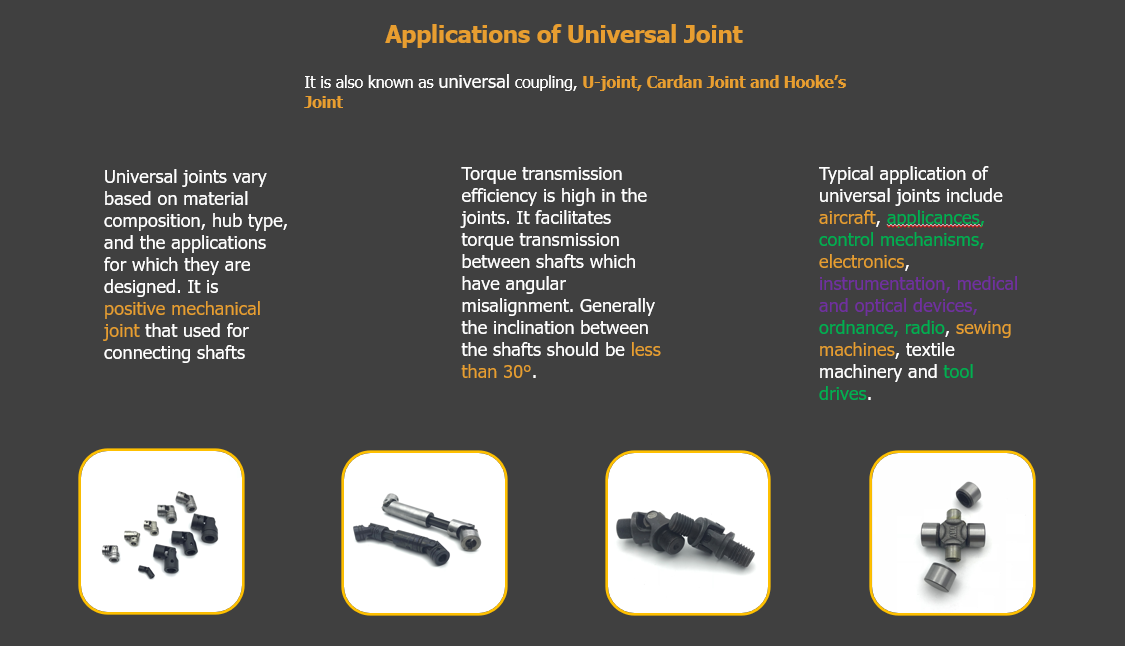

A coupling is a very useful component in industry. It is a device which is used to connect two shafts together at their ends with the aim of transmitting power. The positive coupling of the shafts can be used to transmit rotary power from one shaft to another, where both shafts turn about the same nominal centerline. The application of couplings mainly aims at joining two pieces of rotating equipment while permitting some degree of misalignment or end movement

China manufacturer ductile cast iron shaft coupling for industry

There are various categories of shaft couplings. All the different types have specific applications. The first category is the rigid coupling. When there are requirements for the precise shaft alignment, the rigid coupling will be used. There are also many kinds of this coupling such as the flange coupling and the muff coupling. The second type is the torque limiting coupling which can protect systems against conditions of over torque.

The third type is the flexible coupling. One important function of a flexible coupling is connection of a driving shaft or flange element with an adjacent in-line driven member. Besides, It must flex enough while rotating to accommodate, within limits, undesirable effects caused by axial misalignment, shaft end movement, and vibration between connected members. This kind of couplings can also be further divided into many other types. For instance, three are universal couplings, bellows couplings, disc couplings, jaw coupling, and gear couplings, etc. Taking the bellows coupling as a specific example, this coupling consists of a one-piece flexing element with end hubs which provides both low windup and low side thrust. It has a wide range of usage which is from light industrial power transmission applications to instrumentation. When in the light industries, it can be applied to connect step motors and servomotors to encoders and tachometers.

We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us.

China high quality Auto Car Parts Drive Shafts Shaft Coupling Buffer Block for CHINAMFG Transit 2L1w-4684-AA 2L1w-4684AA 4165078

China wholesaler Drive Pipe Spline Shaft Disc Flange Gear Rubber Jaw Motor Spacer Beam Rigid Fluid Chain Nm Mh HRC Pin Fenaflex Spacer Elastomeric Flexible Gear Coupling

China wholesaler High Torque Transmission Efficiency Drive Shaft Jaw Flexible Coupling for Gearbox

Product Description Excellent powder metallurgy parts metallic sintered parts We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to...

As one of leading drive coupling manufacturers, suppliers and exporters of products, We offer drive coupling and many other products.

Please contact us for details.

Mail:[email protected]